Fab Lab to the rescue: LMC technicians create, donate face shields using 3-D printers

From The Herald-Palladium

Lake Michigan College’s Benton Harbor campus may be closed for the school year, but its Fab Lab is being put to good use.

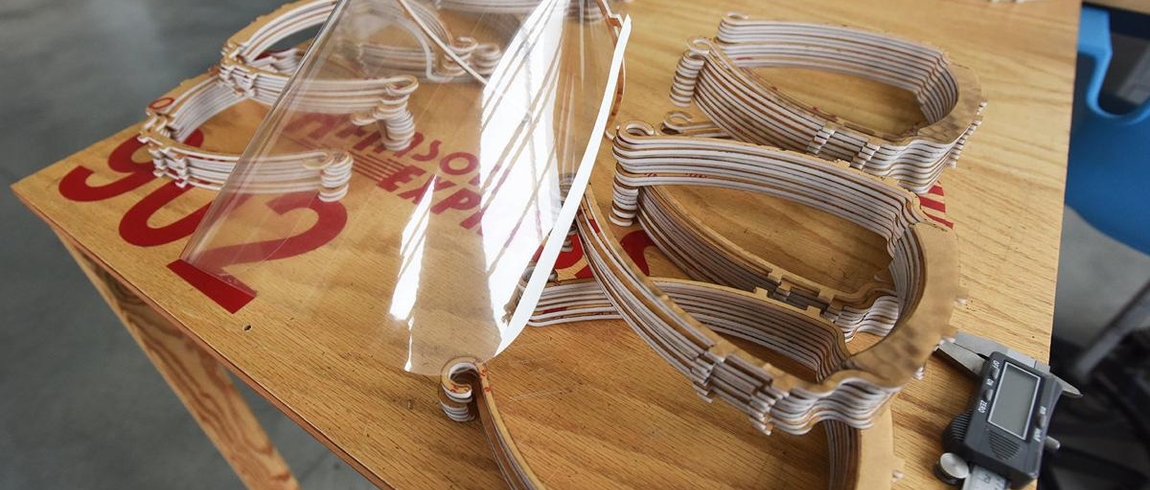

In the midst of the COVID-19 pandemic, a handful of technicians are using LMC’s Fab Lab to produce face shields for police officers and other types of workers who must be out in the field to do their jobs.

Chad Dee, director of the Hanson Technology Center, said the process began by figuring out what the community needed and what materials LMC could secure. They landed on face shields and got to work using the same material that other institutions use.

“We messed around with the files to see what we could do. Reprinting the file took about 65 minutes to print the headband and an additional five minutes to cool off and warm up again,” Dee said. “We inverted the 3-D file into a laser file and we are now able to produce the headband portion of it in a little over a minute.”

Dee said the entire process takes time as 3-D printers don’t work as fast as most think. With the face shields, it takes about 25 layers on the 3-D printer to get through.

“Given the materials that we were able to secure at the time, it takes a while to do the layering,” Dee said. “We were going to go with the lasering as well.”

To produce the main portion of the face shields, volunteers use either 16- or 20-gauge clear marine vinyl.

After they determine which material worked best, Dee said they began reaching out to different organizations and posted on social media to find out who needs them.

“We’ve gotten confirmation from all 21 law enforcement agencies that these are in need,” Dee said. “We’re also reaching out to long-term care facilities. A lot of them have to wear the same mask every day, but wearing a face shield helps protect that mask from getting soiled.”

LMC has also gone to great lengths to ensure the materials are delivered in a sanitary fashion.

Since the coronavirus remains active on plastic and other materials for up to three days, Dee said once the shields are packed and ready to go, they will sit in their respective boxes for three days before people are allowed to pick them up.

As of Wednesday, about 250 shields have been made. Dee said 31 organizations have reached out requesting the shields.

Delivery is expected to begin next week.

Trial and error

For the headband portion of the shields, it took six or seven versions before volunteers found the appropriate size. However, they are still working on a prototype to fit the bands for people with larger heads.

Designing the actual shield was more arduous. Dee said it took nine attempts to get it right on the laser.

“That’s not uncommon with the lab,” he said. “It takes about 10 seconds to assemble them. You snap the two pieces together, which makes it easier for pickup.”

The Fab Lab has received about four different donations so far of the marine vinyl material needed to duplicate the shields. Dee said one large donation of acrylic – which is used for the head bands – is also on the way.

Dee said LMC is being cautious in keeping only one person in the lab at one time, when the 3-D printer is in use for the shields. Throughout the initial process, Dee said one person was there in person to check the durability of the shields by bending the prototypes every which way.

Dee said the time it takes to make a single shield is now down to 2 minutes.

With this in mind, Dee said they hope to make 200 a day if enough material is available.

“We’ve gotten some donations and have a good design,” Dee said. “We’ve requested some people get the word out to see who needs them. It’s quite a big undertaking.”

Dee recommends not calling, as the majority of employees are working remotely. People can expect a quicker response if they email.

The masks will be available for essential workers, from food prep workers to pharmacists and cashiers.

“What we’re asking is if anyone wants them, to email us at the Fab Lab,” Dee said. “Once we have production going, we can start sending them out.”

People with questions about the shields should contact: fablab@lakemichigancollege.edu.

A big effort

In addition to the shields being produced by the Fab Lab, the LMC nursing, dental assisting, medical assisting, pharmacy tech, CNA and natural sciences departments have donated 150 isolation gowns, 86 surgical masks, 110 boxes of gloves, eight boxes of masks, a box of face shields and a pack of protective gowns.

People can contribute to LMC’s other efforts to produce and donate personal protective equipment by visiting the LMC Foundation's Donate page and choosing “Covid Relief Fund.”

Photo provided / The Herald-Palladium